Function

The Schluter-TREP-SE/S/-B are designed and meant to be implemented to protect tiled stair edges with an easily visible, slip resistant, safe, and durable appealing stair-nosing design. The Schluter-TREP-SE/S/-B is suitable for use in heavily trafficked areas such as office buildings, and public buildings. The tread surface of the Schluter-TREP-SE/S/-B is available in a variety of colors; Black, Grey, Light Beige, Nut Brown & Yellow. These pieces can be replaced in case of damage or wear.

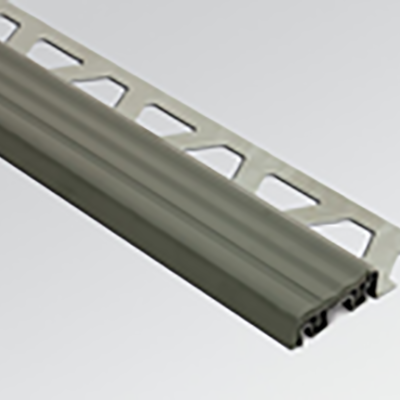

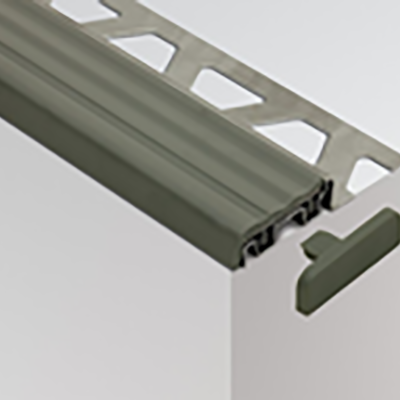

The Schluter-TREP-SE/S/-B feature a trapezoid perforated anchoring leg that is made up of stainless steel (TREP-SE) or aluminum (TREP-S and TREP-B), which is meant to be secured in the mortar beneath the tile. The tread surface meets or exceeds the static coefficient of friction which is recommended in the Americans with Disabilities Act (ADA), for any use in an application where the risk of slipping can occur. The Schluter-TREP-B features a 2 1/8” wide wear surface which makes it convenient to design a staircase with the first and last step marked by a 2” wide strip in a contrasting color to increase safety and visibility.

Installation

- Select Schluter-TREP-SE/-S/-B according to tile thickness.

- Install riser tile flush with the stair tread surface.

- Apply thin-set mortar along edge area above riser.

- Fill cavities on the underside of the profile with thin-set mortar.

- Press the trapezoid-perforated anchoring leg of the profile into the thin-set mortar, making sure the front edge of the profile is aligned flush with the riser tile. Full coverage must be obtained at the edge area to ensure support of the profile.

- Trowel additional thin-set mortar over the anchoring leg and the stair tread surface to ensure full coverage and support of the tile edges.

- Solidly embed the tread tiles so that the tiled surface is flush with the top of the profile.

- A joint of approx. 1/16″ – 1/8″ (1.5 mm – 3 mm) should be left between the tile and the profile.

- Fill joint completely with grout or setting material.

Note: When using Schluter-TREP-TAP, apply Schluter-KERDI-FIX or similar adhesive to the riser and insert the cover profile in the support section of Schluter-TREP-S/-B prior to installing the stair-nosing profile. TREP-TAP should not be used where it can extend past the bottom of the riser.

Material

The Schluter-TREP-SE has a roll-formed stainless steel (304) support section while the Schluter-TREP-S and the TREP-B have aluminum support sections. All three of these profile types feature a slip-resistant thermoplastic rubber thread insert. The Schluter-TREP-TAP is made up of anodized aluminum.

Stainless steel is able to sustain high mechanical stresses and is especially well suited for applications that require it to be resistant again chemicals or acids.

Aluminum must be tested to verify the suitability if any chemical stresses are anticipated in the installation area. When cementitious materials are mixed with moisture they become alkaline which in-turn causes corrosion. It is therefore important to remove any mortar or grout residue from visible surfaces in order to prevent any corrosion resulting from any left-over materials. Also, it is important to ensure that the profile is solidly embedded in the setting material and that all of the cavities are filled in order to further prevent any collection of alkaline water.